What is the difference between Food grade Clean HOCL and common brine-electrolysis HOCL?

The main difference between food grade clean HOCL and common brine-electrolysis HOCL is its production process and quality standards.

Production process: Food grade HOCL is produced through a special electrolysis method, using pure water and food grade salt for electrolysis to ensure the purity and safety of the product.It can produce clean anolyte , no residual salt and no residual NaClO( Sodium hypochlorite). Neutral anolyte pH: 6-7. Hypochlorous acid produced by common brine- electrolysis may use ordinary water and salt for electrolysis, and its production process may not have undergone strict control and monitoring.

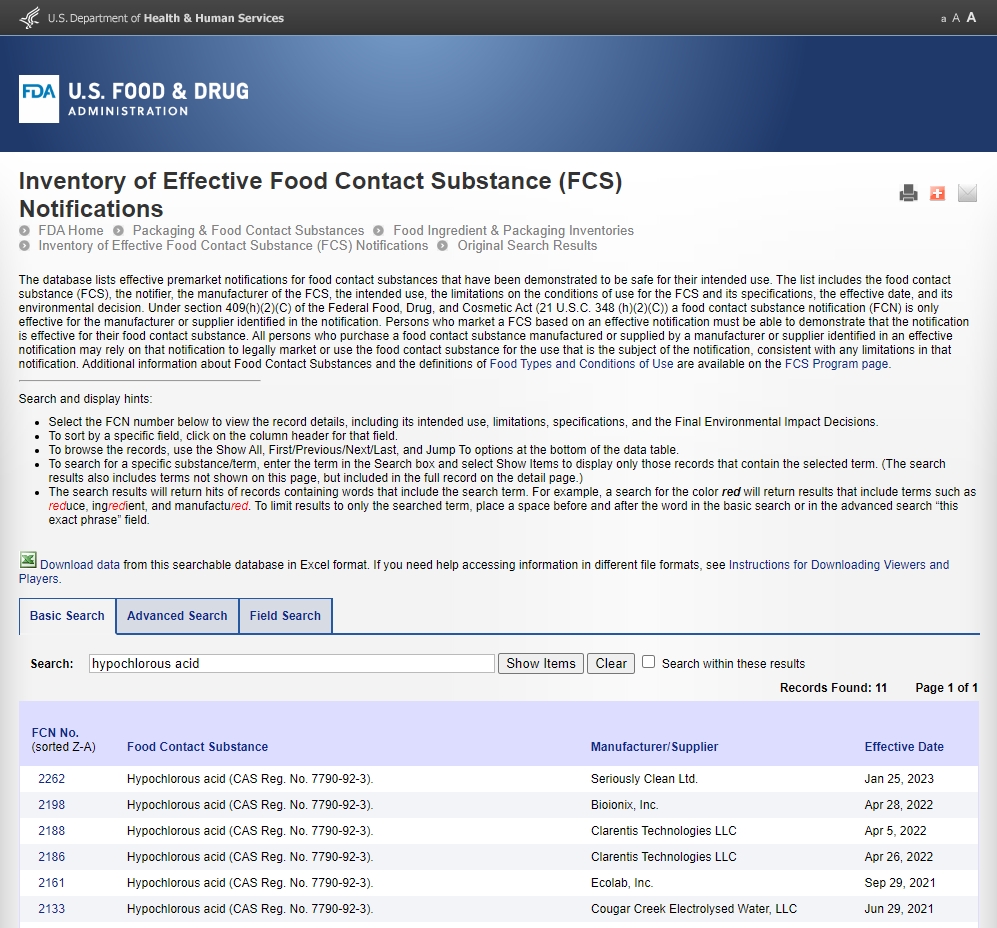

Quality standards: Food grade HOCL needs to comply with food safety standards, such as the requirements of the FDA (Food and Drug Administration). It requires strict testing and validation to ensure that the product is free from harmful substances and microorganisms. Hypochorous acid produced by common brine-electrolysis may not have undergone similar quality standards and testing.

Safety: Food grade HOCL undergoes specialized production processes and quality control, free of residual salt and NaClO(Sodium hypochlorite), ensuring the safety and stability of the product. It can be safely used for food processing and disinfection. HOCL produced by common brine- electrolysis may have unstable quality, contain impurities or harmful substances, and may not be suitable for food related applications.

In summary, food grade clean HOCL is safer, purer, and more suitable for food related applications compared to HOCL produced by common brine-electrolysis.

https://bluewavv.com/e_products/Food-grade-Anolyte-HOCL-Generator-3-19.htmlApplication

Contact Us

Name: Diana

E-mail: [email protected]

Skype: +86-15-22-27-71-011

WeChat: +8615222771011

Whatsapp: +8615222771011

Add: Office N.420D-C1 Tower Ajman,UAE

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry